Material science is an interdisciplinary field that explores the properties, structure, and applications of materials. It involves studying the physical, chemical, mechanical, electrical, and thermal characteristics of substances at atomic and molecular levels. Material scientists aim to understand how a material’s structure influences its properties, enabling them to design and manipulate materials for specific functions.

This field plays a crucial role in various industries, from aerospace and electronics to medicine and construction. Material scientists develop new materials, improve existing ones, and devise innovative manufacturing processes. Sustainability is an increasingly significant focus, leading to the creation of environmentally friendly and recyclable materials.

Material science’s interdisciplinary nature draws from physics, chemistry, biology, and engineering, making it a dynamic and ever-evolving field. It drives technological advancements by discovering novel materials and enhancing their properties, contributing to innovations that impact our daily lives, from advanced electronics to cleaner energy solutions.

Fundamental of material science:

The fundamentals of material science are cantered on understanding the properties, structure, and behaviour of materials at the atomic and molecular levels. Here are the key principles and concepts that form the foundation of material science:

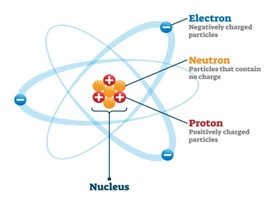

Atomic Structure: Material science begins with an exploration of the atomic structure of materials. Atoms are the basic building blocks of matter, and their arrangement and bonding determine the properties of a material.

Crystal Structures: Many materials, particularly metals and some ceramics, have crystalline structures. Understanding crystallography, which deals with the geometric arrangement of atoms in crystals, is fundamental in material science.

Materials Classification: Materials are categorized into various classes, including metals, ceramics, polymers, composites, and semiconductors, each with unique properties and applications.

Property-Structure Relationships: Material scientists study how a material’s properties, such as strength, conductivity, and hardness, are influenced by its atomic and molecular structure.

Microstructure: Microstructure refers to the arrangement of grains, phases, and defects within a material. It plays a crucial role in determining material properties.

Mechanical Behaviour: Material science examines how materials respond to external forces, including stress, strain, and deformation. Concepts like elasticity, plasticity, and fracture mechanics are essential.

Thermodynamics: Thermodynamics principles are applied to understand the behavior of materials under different temperature and pressure conditions, including phase changes and reactions.

Phase Diagrams: Phase diagrams depict the relationships between different phases of a material as a function of temperature and composition, aiding in material design and processing.

Materials Processing: The methods used to manufacture and modify materials, such as casting, forging, and heat treatment, are integral to material science.

Materials Testing: Material scientists employ various testing methods to evaluate properties like tensile strength, hardness, and electrical conductivity to ensure material quality and performance.

Electrical and Optical Properties: Understanding how materials conduct electricity or interact with light is vital, especially in fields like electronics and optics.

Corrosion and Degradation: Material scientists study how materials deteriorate over time due to environmental factors like corrosion and wear, seeking ways to mitigate these effects.

Nanomaterials: The emergence of nanotechnology has brought a focus on materials at the nanoscale, where quantum effects can influence properties.

Sustainability: As sustainability becomes a priority, material scientists work on developing eco-friendly materials and recycling techniques.

Interdisciplinary Nature: Material science draws from various disciplines, including physics, chemistry, engineering, and biology, making it inherently interdisciplinary.

Classification of Engineering Material:

The factors which form the basis of various systems of classifications of materials in material science and engineering are: (i) the chemical composition of the material, (ii) the mode of the occurrence of the material in the nature, (iii) the refining and the manufacturing process to which the material is subjected prior it acquires the required properties, (iv) the atomic and crystalline structure of material and (v) the industrial and technical use of the material.

1. Metals: Strong and Reliable

Metals are like the workhorses of engineering. They’re super strong and can handle a lot of stress. We can divide them into two groups:

Ferrous Metals:

Steel: The backbone of infrastructure.

Cast Iron: From cookware to engine blocks.

Non-Ferrous Metals:

Aluminum is light and resists rust, so you see it in things like aircraft. Copper is excellent at conducting electricity and heat, making it perfect for wires. Brass and bronze are used for decorations and musical instruments. Lead, though not as common today, is known for being heavy and resistant to corrosion.

2. Plastics: Versatile and Moldable

Plastics are everywhere. They’re lightweight and easy to shape. There are two types:

Thermoplastics: These can be melted and remolded multiple times. Think of plastic bottles, containers, and even toys. Thermosetting Plastics: Once you heat them up and shape them, they stay that way.They’re used for things like car parts and electrical switches

3. Ceramics: Ancient and High-Tech

Ceramics have been around for ages, but they also have modern uses. Two kinds to know:

Traditional Ceramics: These include clay pottery and bricks that have been used for centuries.

Advanced Ceramics: These are high-tech ceramics used in things like space shuttles, electronics, and medical implants.

4. Composites: Blending for Strength

Composites are made by combining different materials. They’re like superhero materials because they have unique properties. You find them in:

Fiber-Reinforced Composites: These mix fibers like carbon or glass with a resin to make strong, lightweight parts. They’re used in aircraft, sports equipment, and even some cars.

5. More Special Materials: For Special Jobs

Semiconductors: These tiny things power our computers and smartphones. Silicon is one of the most famous.

Biomaterials: They’re used in medicine for things like artificial joints. Titanium is one example.

Elastomers: Rubber materials that stretch and bounce back, like the tires on your bike.

Advanced and Smart Materials: Materials like graphene and shape-memory alloys that are still being explored for cool uses.

6. Super Magnets and Conductors

Superconductors: They can conduct electricity with no resistance at super low temperatures. These are important for things like MRI machines.

Ferromagnetic Materials: These are great at making strong magnets and are used in transformers and electric motors.

Engineering Metallurgy:

This includes the study of metallurgy, which is of special interest to an engineer. At the time of taking final decision regarding the selection of suitable material for a particular job, it is essential for an engineer to have a thorough knowledge of engineering metallurgy. This helps him in deciding the treatment processes and their sequence, which are to be carried out on the finished components and structures. This includes the following processes: (i) Iron-carbon alloy system: This deals with the structure of iron and steel as well as iron-carbon equilibrium diagrams. This also deals with the transformation of alloys and steels under various sets of conditions. A detailed and thorough study of this process helps an engineer to decide the suitability of process and the selection of iron alloy for various types of his jobs.

(ii) Heat Treatment: A thorough knowledge of this helps an engineer in deciding the type of process to be undertaken for the smooth and efficient working of the components and structures.

(iii) Corrosion of Metals: This deals with the colossal problem of corrosion of metals and its prevention. It also deals with the processes which help engineers in improving the life and outward appearance of the metal components and structures.